Hobby Nippers: Precision instruments for countless crafting pursuits, these seemingly simple tools demand understanding. From the delicate cuts required in miniature model building to the robust snips needed in jewelry making, the world of hobby nippers is surprisingly diverse. This guide delves into the intricacies of their design, materials, proper usage, and essential safety precautions, equipping enthusiasts with the knowledge to select, maintain, and utilize these vital tools effectively.

We’ll explore the different types of hobby nippers available, analyzing their construction materials and comparing their performance across various applications. Learn essential techniques to maximize precision and longevity, alongside crucial safety measures to prevent accidents. Ultimately, mastering the art of using hobby nippers elevates any crafting project.

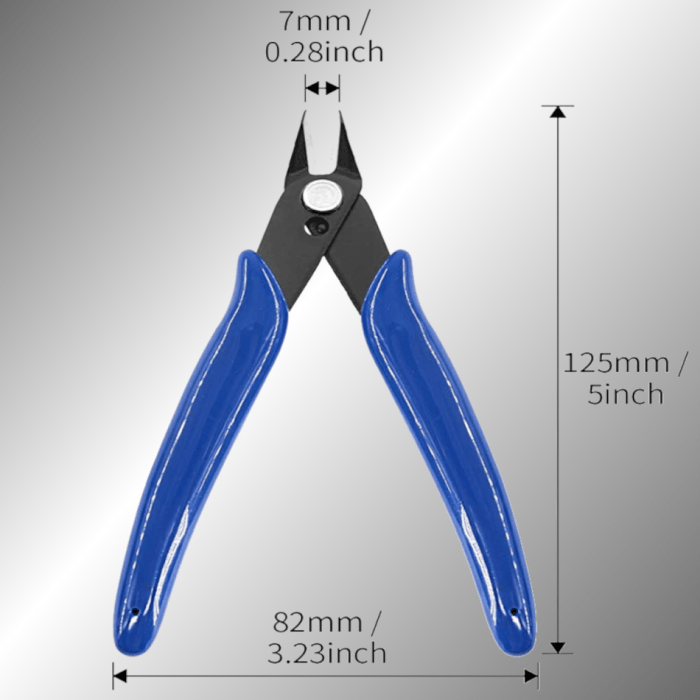

Materials and Construction: Hobby Nipper

Hobby nippers, despite their seemingly simple design, utilize a variety of materials and construction techniques to achieve optimal performance and durability. The choice of materials directly impacts the nipper’s cutting ability, longevity, and overall user experience. Understanding these materials and their properties is crucial for selecting the right tool for a specific task.

Common materials used in hobby nipper construction include high-carbon steel, stainless steel, and various plastics for handles. High-carbon steel is favored for its exceptional hardness and sharpness retention, making it ideal for cleanly cutting plastic model kits and other delicate materials. Stainless steel offers superior corrosion resistance, a valuable asset in humid environments or when working with potentially corrosive materials.

Plastic handles, often made from ABS or similar polymers, provide ergonomic comfort and improve grip, reducing hand fatigue during extended use. The combination of these materials results in a tool that balances cutting performance with user comfort and practicality.

Nipper Design and Functionality

Different nipper designs cater to specific needs and cutting styles. The most common designs include flush-cut nippers, side-cut nippers, and angled nippers. Flush-cut nippers are designed to create a clean, even cut without leaving any significant protruding material. This is essential for precise work in model building, where a smooth finish is paramount. Side-cut nippers feature a cutting edge that is offset from the handle, allowing access to tighter spaces and making them suitable for intricate cutting tasks.

Angled nippers offer a combination of the advantages of flush-cut and side-cut designs, providing versatility for a range of applications. The choice of nipper design depends on the intended application and the level of precision required.

Material Properties and Performance

| Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| High-Carbon Steel | Exceptional sharpness, excellent cutting performance, good durability | Susceptible to rust if not properly maintained | Precision cutting of plastic model kits, electronics work |

| Stainless Steel | High corrosion resistance, durable, long lifespan | Can be slightly less sharp than high-carbon steel, may require more force for cutting | Outdoor use, cutting potentially corrosive materials |

| ABS Plastic (Handles) | Lightweight, comfortable grip, durable, resistant to impact | Can wear down over time with heavy use, not suitable for cutting | Handle material for increased user comfort and ergonomics |

| Spring Steel (in some designs) | Provides assisted opening mechanism, reduces hand fatigue | Can be less durable than other steels, may require more maintenance | Nippers designed for frequent or repetitive use |

Usage and Techniques

Mastering the art of hobby nipping involves more than just squeezing the handles. Safe and effective use requires understanding the tool’s capabilities and limitations, as well as employing appropriate techniques for various materials. Improper use can lead to damaged parts, inefficient cuts, and even injury.Precise cutting with hobby nippers demands a delicate balance of force and control. Applying excessive pressure can lead to crushed or deformed parts, while insufficient pressure results in incomplete cuts.

Furthermore, the angle of the cut and the placement of the nippers significantly impact the final result. Understanding these factors is crucial for achieving clean, precise cuts.

Safe Operating Procedures

Safe operation of hobby nippers begins with proper handling. Always hold the nippers firmly, but avoid applying excessive force. Keep fingers clear of the cutting blades during operation. Use a cutting mat to protect your work surface and prevent accidental damage. Regularly inspect the nippers for damage, such as dull blades or loose joints, and replace them if necessary.

Ignoring these precautions can lead to accidents and inefficient work. A firm, controlled grip and awareness of the blade’s position are paramount.

Common Mistakes to Avoid, Hobby Nipper

Several common mistakes can hinder the effectiveness and safety of using hobby nippers. One frequent error is applying too much pressure, leading to crushed or deformed parts. Another is using dull or damaged nippers, resulting in jagged cuts and increased effort. Incorrect cutting angles can also lead to imprecise cuts and potential damage to the material. Finally, failing to use a cutting mat can damage work surfaces and increase the risk of injury.

Addressing these issues ensures cleaner cuts and a safer working environment.

Cutting Techniques for Various Materials

The optimal technique for using hobby nippers varies depending on the material being cut. Employing the correct method ensures clean cuts and prevents damage to the material or the nippers themselves.

- Plastic: For plastic sprue, a firm, controlled cut is usually sufficient. Avoid excessive pressure to prevent crushing or warping. A slight rocking motion can help create a cleaner cut.

- Metal: Cutting metal requires more force and may necessitate multiple cuts. A slow, steady approach is recommended to prevent bending or damaging the nippers. Using lubrication, such as cutting oil, can help reduce friction and improve the cut.

- Resin: Resin often requires a sharper blade and a more precise cut. Avoid excessive pressure to prevent chipping or cracking. A gentle, controlled squeeze is usually sufficient.

- Thin Wire: For thin wire, a precise, controlled cut is essential. Use a smaller pair of nippers if available, and avoid excessive force to prevent the wire from bending or deforming.

Whether you’re a seasoned model builder or a novice crafter, understanding the nuances of hobby nippers is paramount. From selecting the right tool for the job to mastering safe handling techniques and implementing proper maintenance, this guide has provided a comprehensive overview. By embracing these insights, you can significantly enhance the precision, efficiency, and safety of your crafting endeavors, unlocking new levels of creativity and skill.