Hobby Wheel, a term encompassing a surprisingly diverse range of tools and equipment, takes center stage. From precision instruments for model making to robust components for larger-scale projects, hobby wheels represent a fascinating intersection of craftsmanship, technology, and passion. This exploration delves into the materials, applications, and communities surrounding these often-overlooked yet essential tools, revealing their surprisingly significant role in numerous hobbies and creative pursuits.

This report will examine the various types of hobby wheels, their construction, maintenance, and the vibrant communities that have grown around them. We’ll explore the future of hobby wheel technology and consider how innovation might shape this niche market. The analysis will also include a comparative study of different hobby wheel types, highlighting their unique features and applications.

Defining “Hobby Wheel”

The term “Hobby Wheel,” while not formally standardized, refers to a broad category of small, typically manually powered wheels used for various craft, hobby, and artistic pursuits. These wheels serve as essential tools for a range of activities, from spinning fibers for yarn to shaping clay or metal. Their design and functionality vary significantly depending on the intended application.

Understanding the nuances of different hobby wheels is crucial for selecting the appropriate tool for a specific task.

Types of Hobby Wheels and Their Applications

Hobby wheels encompass a diverse array of tools, each tailored to a specific craft. They can be broadly categorized based on their function and the materials they manipulate. These categories are not mutually exclusive, and some wheels may overlap in functionality.

Comparison of Hobby Wheel Types

The following table compares three distinct types of hobby wheels, highlighting their key characteristics:

| Type | Materials | Typical Uses | Price Range |

|---|---|---|---|

| Spinning Wheel | Wood, metal, plastic; often incorporates components like a flyer, whorl, and bobbin. | Spinning yarn from fibers such as wool, cotton, or silk. Used for creating handspun yarn for knitting, weaving, or other textile arts. | $100 – $1000+ (depending on complexity and materials) |

| Pottery Wheel (Miniature) | Ceramic, plastic, or metal; often electric or manual. | Shaping clay for small-scale pottery projects. Suitable for creating miniature figurines, decorative items, or small bowls. | $50 – $300+ (depending on size, features, and motor type) |

| Jeweler’s Wheel (Bench Wheel) | Metal; usually includes a rotating head and various attachments. | Shaping and forming metal, often used in conjunction with other jewelry-making tools. Used for tasks like wire wrapping, bead setting, and creating intricate metal designs. | $150 – $500+ (depending on size, construction, and features) |

Materials and Construction

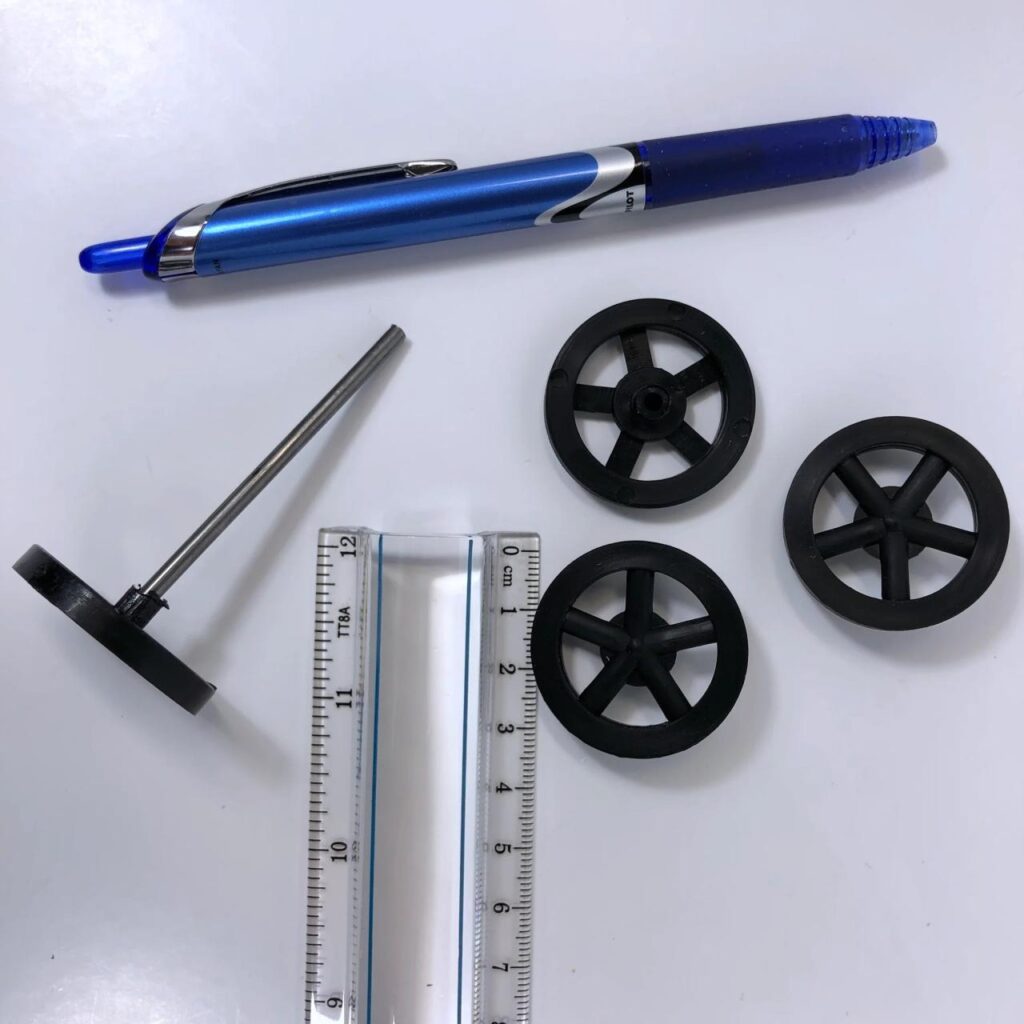

Hobby wheels, despite their seemingly simple design, rely on a careful selection of materials and precise manufacturing techniques to ensure durability, performance, and aesthetic appeal. The choice of materials significantly impacts the wheel’s weight, responsiveness, and overall lifespan, while the construction methods determine its structural integrity and resistance to wear and tear.The most common materials used in hobby wheel construction are plastics, wood, and metals.

Each offers a unique set of advantages and disadvantages, influencing the final product’s characteristics and target user.

Plastic Hobby Wheels

Plastic, particularly ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, is prevalent due to its low cost, ease of molding, and relatively high impact resistance. ABS offers a good balance of strength and flexibility, making it suitable for many hobby wheel applications. Polycarbonate, while more expensive, boasts superior impact strength and transparency, often preferred for visually appealing or specialized wheels. However, plastics can be susceptible to wear and tear, particularly under heavy loads or abrasive conditions.

The inherent flexibility of some plastics can also lead to deformation over time, affecting the wheel’s performance. Manufacturing typically involves injection molding, a highly efficient process capable of producing large quantities of identical wheels quickly and cost-effectively.

Wooden Hobby Wheels

Wooden hobby wheels, often crafted from hardwoods like maple or birch, offer a unique aesthetic appeal and a different feel compared to their plastic counterparts. The natural grain and variations in wood contribute to the wheel’s unique character. Hardwoods provide good strength and durability, but they are susceptible to moisture damage and require careful finishing to prevent warping or cracking.

Manufacturing typically involves lathe turning, a skilled process requiring precision and expertise. This method allows for intricate designs and precise dimensional control but is less efficient and more labor-intensive than injection molding, resulting in higher production costs.

Metal Hobby Wheels

Metal hobby wheels, usually constructed from aluminum or steel alloys, are often favored for their high strength and durability. Aluminum alloys offer a good balance of strength and lightweight properties, making them ideal for applications requiring high performance. Steel alloys, while heavier, offer superior strength and resistance to wear and tear, particularly beneficial in high-stress environments. However, metal wheels are typically more expensive to produce and can be more challenging to manufacture due to the required machining processes.

Manufacturing typically involves CNC machining, which allows for precise control over the wheel’s dimensions and intricate designs, but this process is more time-consuming and costly than injection molding or lathe turning.

Innovative Materials and Construction Techniques

High-end hobby wheels sometimes incorporate innovative materials and construction techniques to enhance performance and durability. For example, the use of carbon fiber reinforced polymers (CFRP) provides exceptional strength-to-weight ratios, resulting in lighter and more responsive wheels. 3D printing techniques are also gaining traction, allowing for the creation of complex designs and customized wheels with intricate geometries not easily achievable through traditional methods.

These advancements push the boundaries of hobby wheel design and performance, catering to discerning users seeking superior quality and functionality.

The world of hobby wheels, while seemingly small, reveals a depth and complexity that belies its unassuming nature. From the meticulous craftsmanship evident in high-end models to the simple functionality of basic designs, hobby wheels demonstrate the power of specialized tools to unlock creative potential. As technology advances and communities continue to thrive, the future of hobby wheels appears bright, promising innovation and further diversification within this intriguing niche.